Reliable, weather-resistant, and age-proof brick remains an ideal building material. Innovation, in terms of masonry techniques, means brick can be used in evermore inventive ways, allowing a solid, stylish finish to homes and a range of buildings. Here, Scott Denham, Sales Director at IG Masonry Support, looks at how manufacturing expertise and design technology are bringing a new look to traditional brickwork.

Due mainly to its consistent shape, compressive strength and ability to absorb water, many generations of architects have selected brick as their go-to building material. Its popularity hasn’t gone

unchallenged, however, with the past decade or so seeing the emergence of solutions such as cladding. But in keeping with the well-known phrase, ‘form is temporary, class is permanent’, brick is back in vogue as an inspiration to property owners and designers looking to emulate modern interpretations of classic architecture.

Architecturally, the intricate detailing that brickwork enables is without compare. Brick detail in the form of brick soffits, brick feature arches, deep reveals and flying beams continually make for stunning exteriors, enabling architects to create truly unique facades. Brick’s popularity in the UK and Ireland as a tried-and-trusted building source was unrivalled until modern composite cladding systems containing materials such as steel, concrete and aluminium offered a quicker, cheaper route to creating bright, contemporary-looking buildings. Such convenience comes at a cost, however. Aesthetically, modern cladding systems can begin to look tired and dated over time, thus regular and potentially costly maintenance can be needed to upkeep or upgrade them. This brings into question their long-term cost efficiency, but not-so-brick-built facades, which will retain their impressive look many years after their initial construction.

A bespoke solution

At IG Masonry Support, not only do we understand that architects need to be given creative authority over prefabricated brick features, we realise the importance of regulatory compliance and quality.

Achieving deep brick soffits and intricate brick bonds around window heads and openings is quick, easy and cost-efficient to achieve with our Brick On Soffit Systems (B.O.S.S. and B.O.S.S.+). These tailor-made bespoke solutions are designed and manufactured to meet the client’s specification. The systems are highly adjustable, enabling architects to design various shapes and depths of brick soffits whilst accommodating a wide range of bond patterns.

To meet changes to Building Regulations, IG Masonry Support engineered B.O.S.S.+, an A2 fire-rated system suitable for use on projects that require Building Regulations Document B compliance. The second generation of its original B.O.S.S. system, B.O.S.S.+ comprises a stainless-steel framework with a cement particle board backing element to which the brick slips are adhesively bonded and mechanically fixed. In short, this BBA-certified solution ticked the boxes in all of the required areas and was available to the market in 2019.

Not resting on its laurels, IG Masonry Support’s next step was to create a fully non-combustible and carbon-neutral product. The BBA-certified B.O.S.S. A1 system is ‘A1’ fire rated and has been subjected to hygrothermal testing. The product passed the rigorous examination with ease. As well as meeting current fire regulations regardless of the building’s height or purpose, the manufacturing process and environmental impacts will be significantly reduced.

Marlborough Primary School

IG Masonry Support’s B.O.S.S. system was selected as the ideal solution to create a stunning brick detail around large, circular windows, which form part of a major redevelopment at Marlborough Primary School in west London. The window feature, designed in conjunction with the project’s lead architect Dixon Jones, required IG Masonry Support to prefabricate a series of imposing circular-form B.O.S.S. deep soffit systems containing green-glazed slip bricks. The soffits’ shape and colour acknowledge the polychromy of a nearby 1911 Michelin building. In situ, this magnificent brick detailing brings an exciting, creative energy to the refurbished school’s vibrant new learning environment.

Alison Gingell Building, Coventry University

A new health and science building at Coventry University offers a fine example of how innovative masonry techniques have revolutionised brick’s use as a design accessory. The Alison Gingell Building was created to provide students with ‘world-class facilities’, enabling them to learn in situations that mirror real-life scenarios. Following consultations with architect Broadway Malyan, IG Masonry Support supplied the building’s standout architectural feature: 23 large-scale brick slip fins, which appear throughout the health and science block’s south elevation. The prefabricated fins were designed and manufactured by IG Masonry Support using slip bricks within a brick panel system, which the company developed to allow designers and specifiers to achieve a deeper soffit that blended seamlessly with surrounding brickwork.

Time and cost savings

No matter how ambitious the design, IG Masonry Support’s easy-to-install solutions deliver significant reductions in installation time by up to 90%. Any higher initial costs can be offset by saving time and money in terms of labour. A quality finish that meets the required aesthetics and blends seamlessly with the surrounding brickwork can also be achieved.

As with a beloved work of art, brick is a design classic that will continue to be rediscovered by future generations. It will ensure brick’s relevance to private homes and public buildings that will gain in style but lose nothing in terms of stature and safety by the additional design possibilities it now allows. This is due in part to companies such as IG Masonry Support and their commitment to developing solutions that enable brick, a staple construction material, to be used in ways that fire the imagination of architects and builders alike.

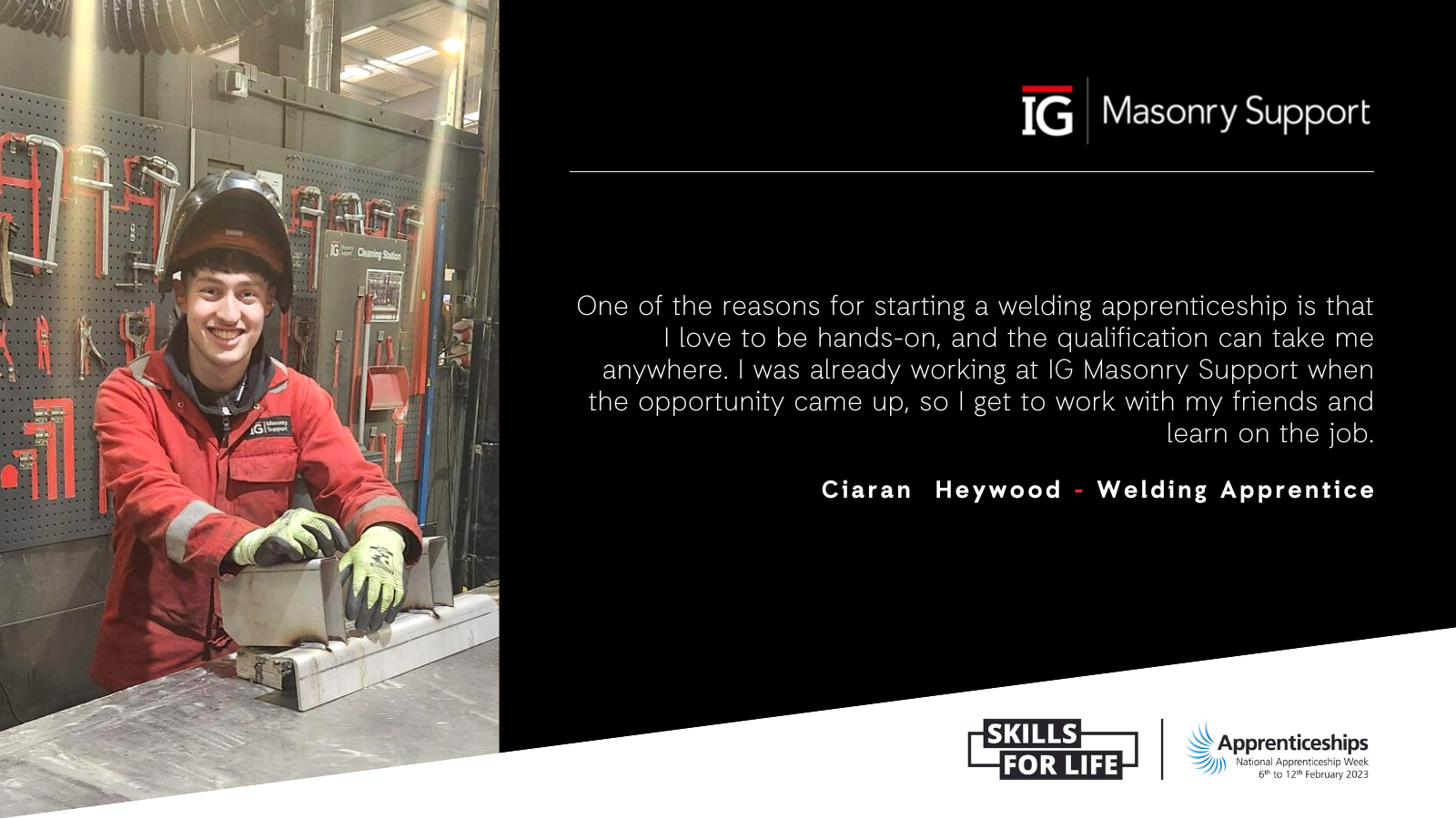

For school leavers, there is a world of opportunity available to develop a career at IG Masonry Support. As well as great mentoring and training, you will be working and gaining the skills to achieve fast career progression.

For school leavers, there is a world of opportunity available to develop a career at IG Masonry Support. As well as great mentoring and training, you will be working and gaining the skills to achieve fast career progression.