Downloads & Resources

- BBA – IG B.O.S.S – May 2024

- B.O.S.S. – Environmental Product Declaration – September 2022

- BBA UK Certificate of Conformity of the Factory Production Control – Aug 2023

- Eurofins Certificate of Conformity of the Factory Production Control – Sep 2021

B.O.S.S.

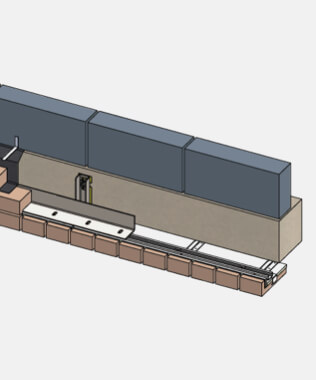

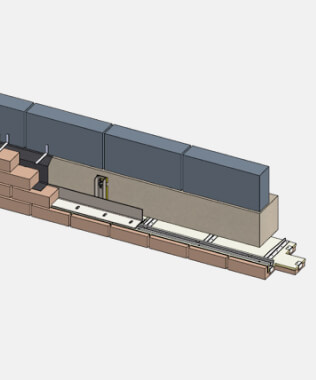

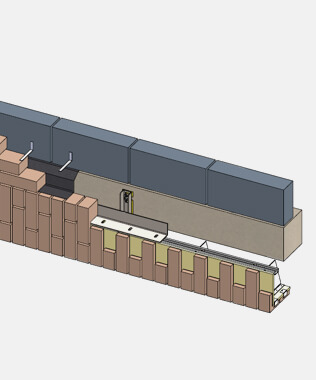

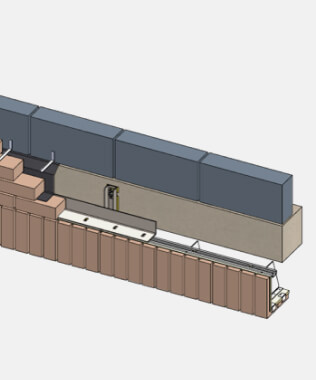

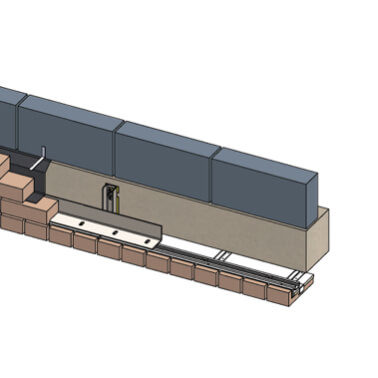

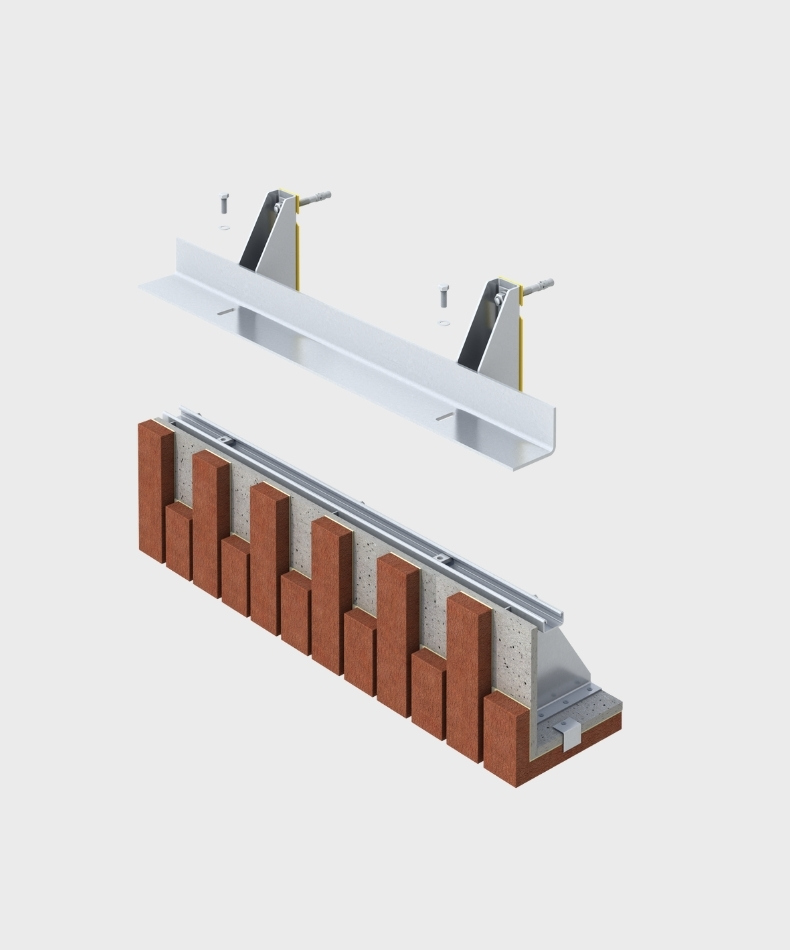

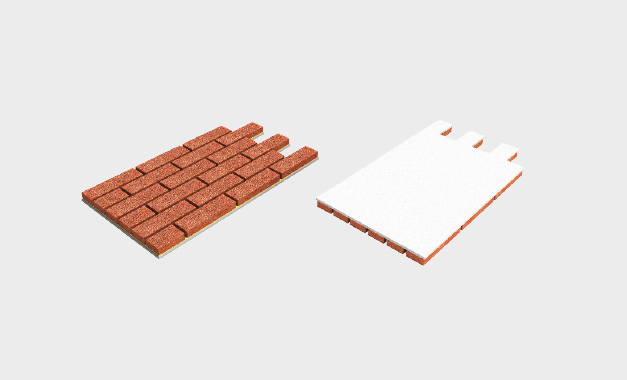

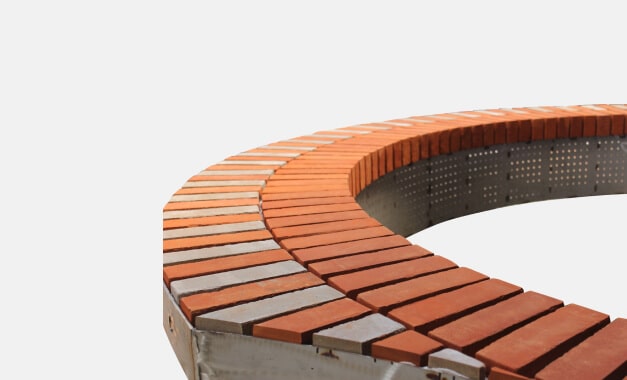

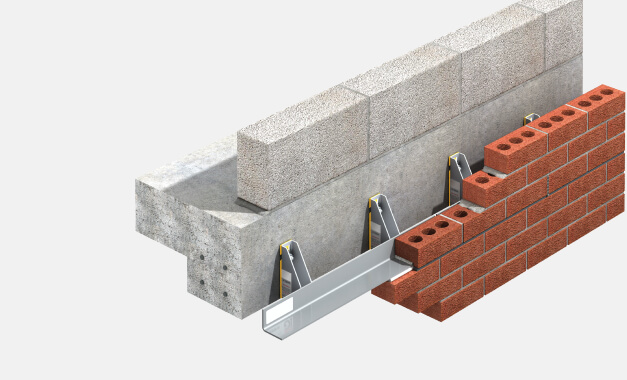

B.O.S.S. is a lightweight, stainless steel, prefabricated brick slip soffit system designed to be quickly and easily bolted to IG’s Welded Masonry Support (WMS) to create spectacular brick soffits.

Manufactured off-site, the prefabricated components are delivered to site complete with brick slips adhesively bonded to the stainless steel carrier unit. The lightweight system facilitates fast and efficient installation. Installation time on-site can be reduced by up to 90% and the need for mechanical lifting is removed as B.O.S.S. units are 70% lighter than equivalent concrete units.

Application

Brick soffits, deep reveals and flying beams have become increasingly popular design features with architects wanting to add depth and visual flare to a masonry façade. IG’s B.O.S.S. system provides a technically advanced solution that meets the required aesthetics, producing completely hidden structural steel work which gives the impression of unsupported brickwork.

Adjustability

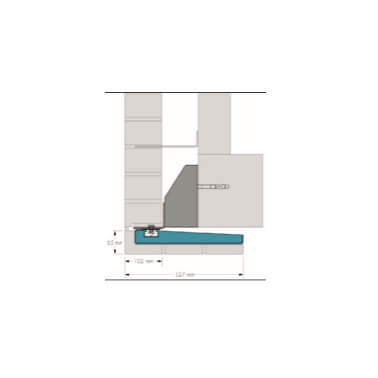

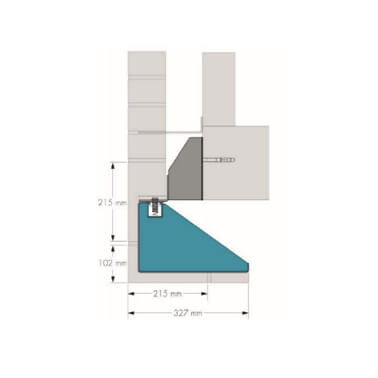

B.O.S.S. is a two part system designed to be fitted to the underside of IG’s Welded Masonry Support (WMS) and offers adjustability on all three planes.

The Masonry Support Shelf is supplied with a slotted hole, giving adjustability along the Z axis. Further adjustment on the Z axis is attained by shimming behind the Masonry Support Bracket.

The integrated channel in the B.O.S.S. unit allows for increased adjustment on the X axis. Adjustability on the Y axis is created within the Masonry Support Bracket, and the ability to insert shims between the Shelf and the bolt-up System.

B.O.S.S. Typical Design Solutions

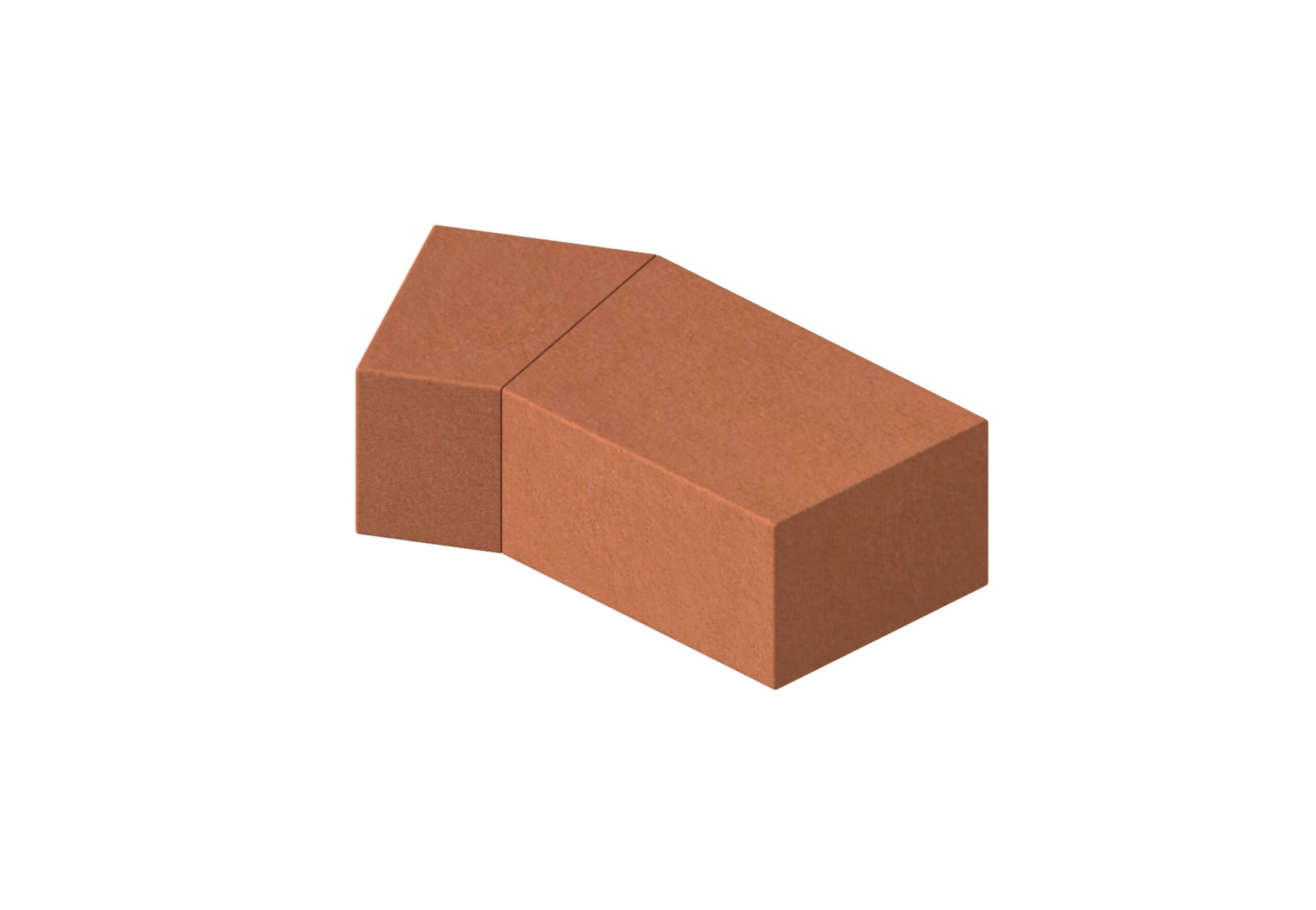

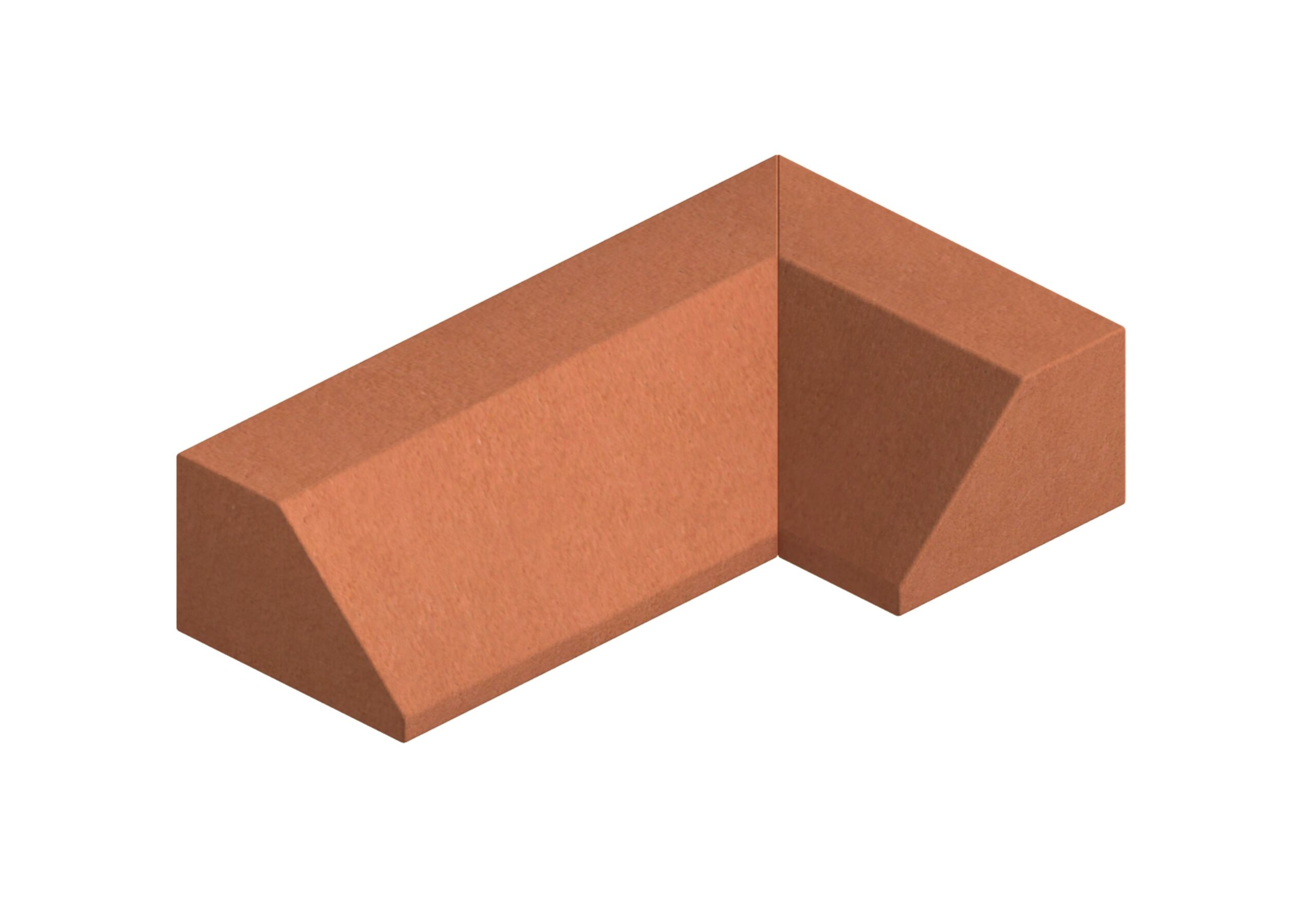

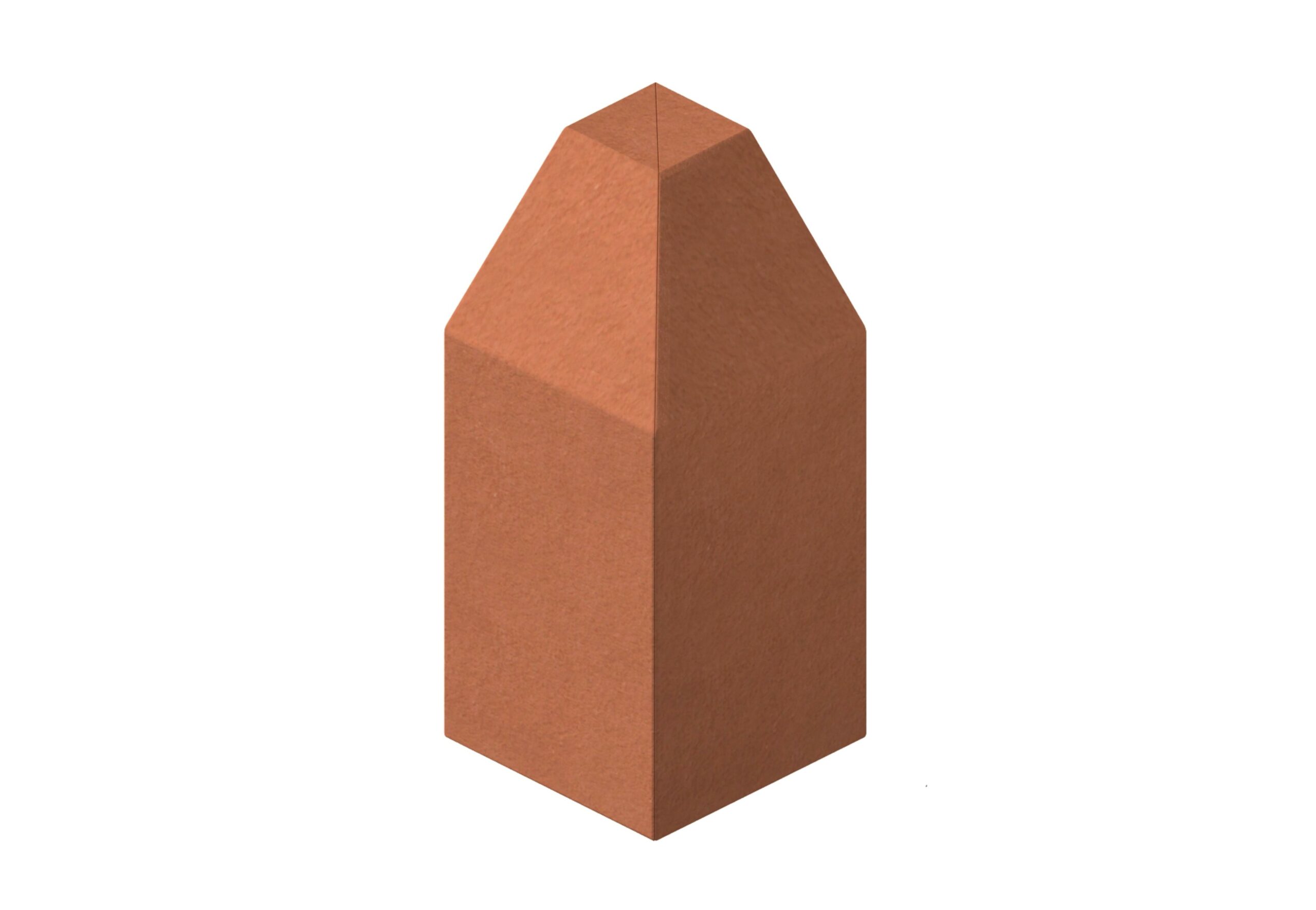

B.O.S.S. creates spectacular brick soffits with a wide range of bond patterns. The System is available in many profiles, four of which are shown below. Bespoke solutions including other brick arrangements are designed by our engineers to suit specific project requirements.

Design Service & Support

IG Masonry Support’s designers and engineers provide a complete 3D CAD design and structural engineering service and will develop your concept into quality, cost effective prefabricated brick slip soffit solutions.

Installation of B.O.S.S.

Correct installation is essential for the success of your project. Therefore, we have made every effort to help you by creating an easy-to-use installation guide for B.O.S.S.

B.O.S.S. Brick on Soffit System (Bolting to WMS) Installation Guide (2,008kb)

Should you have any technical questions prior to or during installation, please call +44 (0)1283 200157 for friendly straightforward advice.

Discuss Your Project

Contact our technical design team to collaborate or enquire about a project.

Contact UsB.O.S.S. Typical Design Solutions

B.O.S.S. creates spectacular brick soffits with a wide range of bond patterns. The system is available in many profiles which are shown below. Bespoke solutions including other brick arrangements are designed by our engineers to suit specific project requirements.

Related Products

B.O.S.S. A1

Bonding Bricks

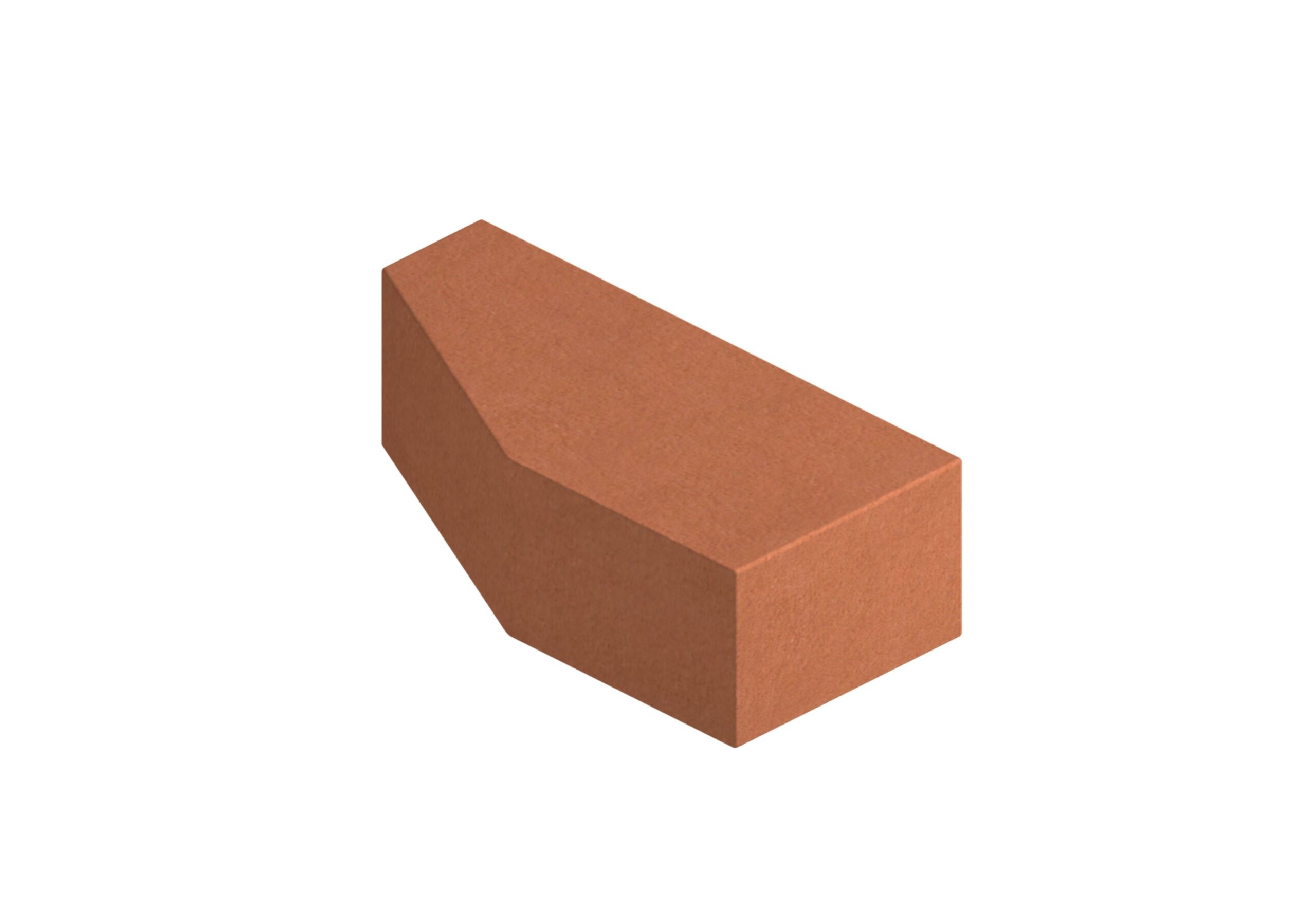

Arch Bricks

Angle and Cant Bricks

IG Brick Panel System

Brick Slip Arches

Brick Slip Lintels

Plinth Bricks

Refacing and Tinting

Shelf Angle Bricks

Slip Bricks

Soldier Bricks

Welded Masonry Support

Projects using these products

Projects using these products

Projects using these products

Projects using these products

Projects using these products

Projects using these products

Projects using these products

Projects using these products

Projects using these products

Projects using these products

Projects using these products

Key Benefits of B.O.S.S.

Contact Us- Simplicity of installation

- No brick cutting required on-site

- Support steelwork is completely hidden

- Adjustability in all planes

- Various bond patterns and soffit sizes available

- Blends seamlessly with surrounding brickwork

Request CPD Presentation

Gain your CPD points by requesting a Continuous Professional Development presentation on IG Masonry Support solutions.

Request CPD