By Andy Neal, Managing Director, IG Masonry Support

Sustainability is at the forefront of the minds of many construction businesses, most notably because of the key role it plays in tackling the worldwide climate change crisis. As the UK aims for net zero carbon emissions by 2050, companies across the nation will have to take matters into their own hands to make each and every corner of their business more sustainable. This is a sizeable change which cannot happen overnight – instead it needs to be broken down into achievable, smaller increments. With this in mind, which considerations can manufacturers and suppliers make to attain net zero goals?

In order for the construction industry to be more sustainable and reach the net zero carbon target by 2050, everyone in the supply chain has to take action. Creating energy efficient buildings will only prove truly successful if they feature products that have low environmental impact from their production, through to their use and disposal at end of life. Every business should be starting to push towards net zero carbon emissions if they haven’t already, and it is the responsibility of all construction companies to make the changes that are needed.

For us here at IG Masonry Support – and as a leader that many others look up to – we had to ensure we were taking the right course of action for our business to achieve this goal. As a team we are passionately committed to becoming as carbon conscious as possible, and believe this neutrality shouldn’t stop at product innovation. It should be a fundamental cornerstone of a company’s entire culture.

We realise that achieving net zero carbon is no easy feat; remember this is a marathon, not a sprint. For this reason, we decided to take the initial step by looking at how we could introduce a product that was carbon neutral. This has planted the seed of our net zero aim, enabling us to learn from this process and look at how we can implement business-wide.

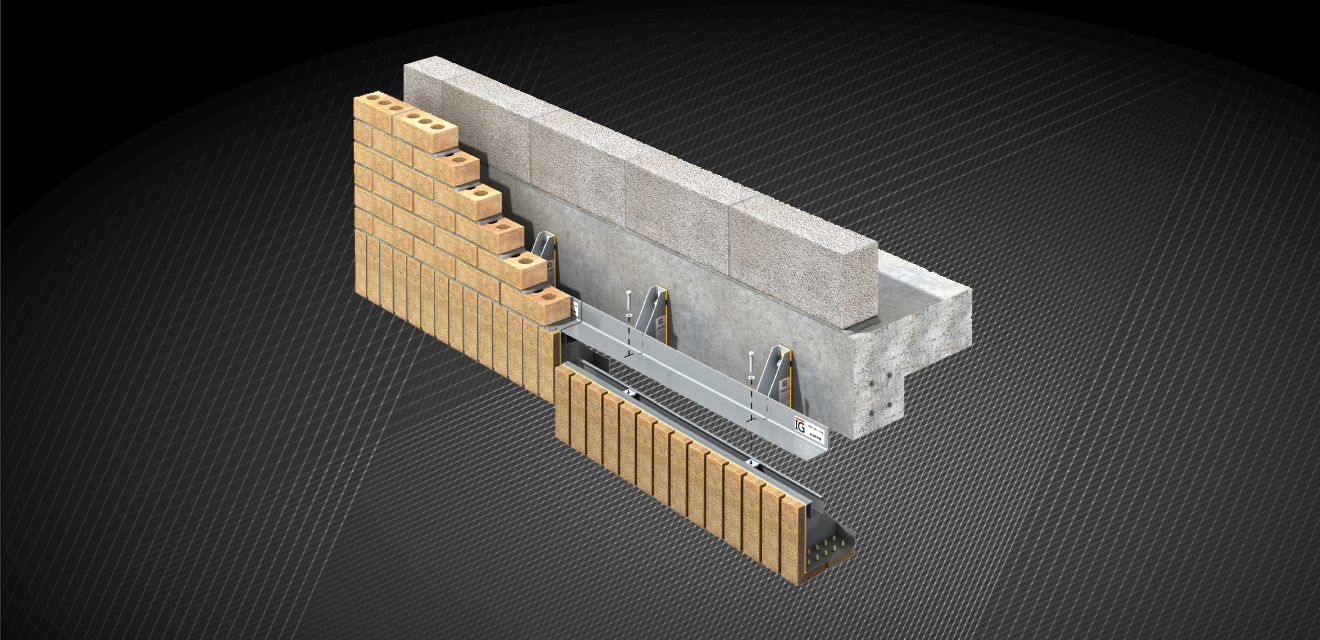

The launch of IG’s new B.O.S.S. A1 product is the first step in our net zero carbon journey. It is kickstarting our desire to be a carbon neutral organisation by 2021. It will create a legacy for itself as our original carbon neutral product – you better be assured it definitely won’t be our last! The product is an evolution of our market leading brick on soffit system that is lauded by so many. We are proud to say this BBA certified product is A1 fire rated; it has been given the non-combustible seal of approval, meaning this product can be specified on buildings of any height. The product boasts all the excellent qualities of the fellow B.O.S.S. ranges: lightweight, easy-to-install, less labour-intensive.

To make it a carbon neutral product, we have offset carbon emissions through certified carbon offset projects. We realise that offsetting itself is not going to solve the problem, which is why we are committed to ensuring the volume we offset reduces each year. We all have to start somewhere, and taking smaller steps at the beginning will enable us to make the greater leaps that are needed.

At IG we sought an independent body to offer advice on how to be net zero completely, and have made it our mission to go beyond offsetting the costs. Not only have we changed from diesel to electric forklift trucks, we’ve purchased new fibre laser machines that are more efficient, and all delivery vehicles produce as low emissions as possible. We’re just getting started!

In the five years IG Masonry Support has been around, we have grown considerably. What we want to do now is to continue that development, bringing innovative products to the marketplace in the most sustainable, carbon neutral way. It is the route we can take to suppress climate change, and we encourage friends from across the sector to do their bit and follow the same path.