- Home

- Masonry Support Systems

- Welded Masonry Support

Downloads & Resources

-

Certifications

- Passive House – Welded Masonry Support

- WMS – Environmental Product Declaration

- Eurofins Certificate of Conformity of the Factory Production Control

- BBA UK Certificate of Conformity of the Factory Production Control

- Constructionline Gold Member

- Eurofins Welding Annex

- BBA – Welded Masonry Support

-

Declaration of Performance

- Load Bearing and Welded Structural Steel Components – UKCA

- Load Bearing and Welded Structural Steel Components – CE

-

Brochures

- Full Product Brochure

-

Installation Guides

- Welded Masonry Support Installation Guide

Links

Product Overview

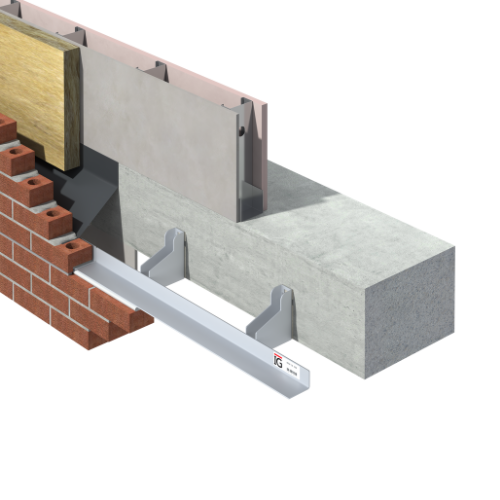

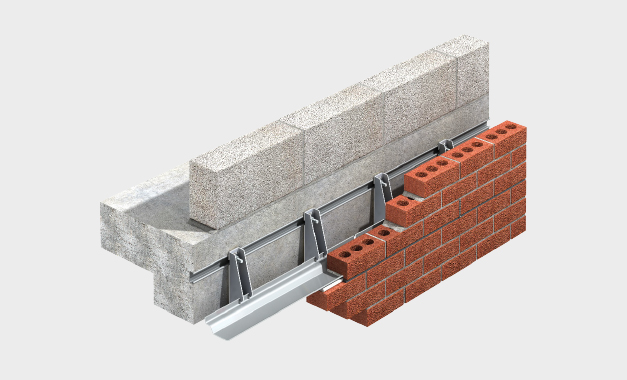

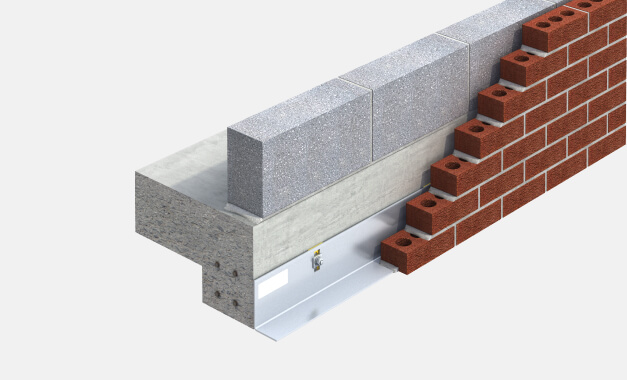

IG’s Welded Masonry Support (WMS) is a rigid masonry support system comprising fixed brackets welded to a stainless steel angle support shelf.

There are several variations of the standard IG WMS system which are designed and manufactured to engineers’ specifications on a project basis. These variations include:

- WMS Standard – suitable for applications where the support level aligns with the base of the structural frame.

- WMS Dropper – suitable for applications where the support level is below the line of the base of the structural frame.

- WMS Cavity Closer – suitable for applications where the support level is in line with the base of the structural frame, and when a cover is required to the underside of the

angle support shelf to conceal the cavity in the building. - WMS Inverted – suitable for applications where the support level is in line with the top of the structural frame.

- WMS Plaster Key – suitable for applications where the support level is in line with the base of the structural frame, and when a render finish is required to the underside of the angle support shelf.

- WMS Notched – suitable for applications where the support level is below the line of the base of the structural frame and when the brackets need notched to avoid a clash

with another element within the building.

Each variation is designed to support brickwork and blockwork in a building façade and fix back to the structural frame of that building. Each system is supplied with lock washers, shims and fixings to aid installation.

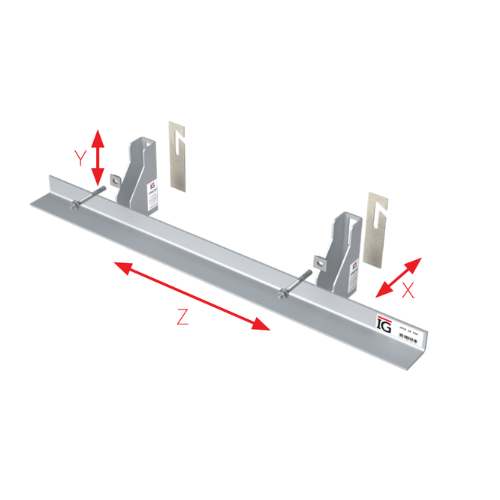

WMS is designed and manufactured to engineers’ specifications on a project basis and offers three planes of adjustability onsite.

Certification and Accreditations

IG’s Welded Masonry Support systems are certified with the Code for Construction Product Information (CCPI) mark, thereby guaranteeing information clarity, accuracy, and regulatory compliance.

Adjustability

IG’s Welded Masonry Support provides adjustability on three planes to ensure that building tolerances can be accommodated and contact with structural reinforcing bar can be avoided.

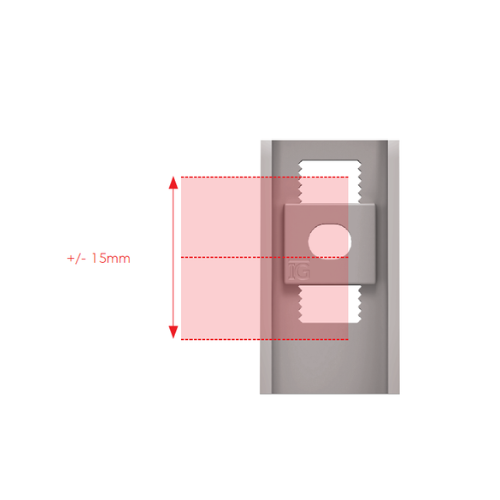

Vertical adjustment

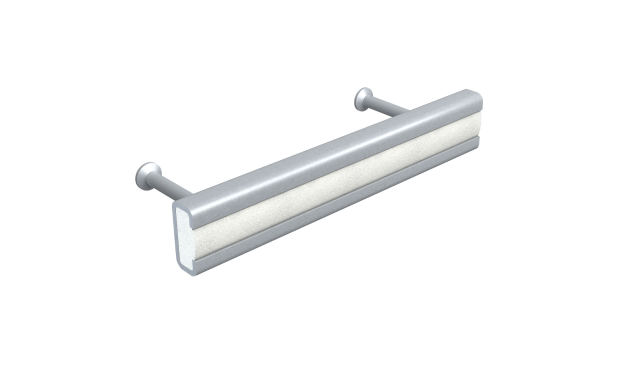

Vertical adjustment is offered by means of a toothed Lock Washer which is inserted into the serrated slot in the support bracket. The lock washer can be adjusted vertically to move the bracket higher or lower. The serrated area at the back of the bracket allows up to 15mm of adjustment in either direction on the vertical plane.

Lateral Adjustment

The Lock Washer also providers lateral adjustment via the oval-shaped hole in the washer. The fixing can be moved +/- 2mm laterally to allow for fine adjustment.

Shimming

To accommodate a small increase in cavity width, shims can be inserted between the support structure and the brackets. Thermal shims are provided as standard to reduce thermal bridging in a thickness of 2mm and stainless steel shims are available to order in a range of thicknesses (3, 4, 5 and 6mm).

Product Design and Testing

Masonry support falls within the scope of harmonised European Standard BS EN 1090-1:2009 +A1:2011 Execution of steel structures and aluminium structures: requirements for conformity assessment of structural components. IG Masonry Support comply with all Construction Product Regulations (CPR), UKCA and CE marking requirements of this Standard, including designs to EN 1993 (Eurocode 3) and external certification of factory production controls by an approved body.

IG Masonry Support is certified by the British Board of Agrément and Eurofins to undertake welded fabrication work to Execution Class 2 according to BS EN 1090-2:2018.

All IG Masonry Support’s structural products are designed to meet the durability standard outlined in BS EN 1993-1-4: Eurocode 3 – Design of steel structures.

A1 Non-combustible Materials

All IG Masonry Support’s masonry support systems are manufactured from 304/304L Austenitic Stainless Steel (1.4301/1.4307) or 316/316L (1.4401/1.4404) on request. Stainless steel is considered A1 fire-rated without the need for testing in accordance with the guidance of the European Commission Paper 96/603/EC as referenced in BS EN 13501-1:2018.

IG Masonry Support’s Thermal Shims are supplied as standard with every masonry support system and are A1 fire-rated having been tested and classified in reaction to fire in accordance with BS EN 13501-1:2018.

Thermal Conductivity

Approved Document L Volume 2 places specific emphasis on the performance of building details and the additional heat losses through linear thermal bridging. To support this requirement, all IG Masonry Support’s masonry support systems are manufactured from 304/304L Austenitic Stainless Steel (1.4301/1.4307) or 316/316L (1.4401/1.4404) on request. Stainless steel has among the lowest thermal conductivity of any metal at approximately 15 watts per kelvin per metre.

IG also supply a Thermal Shim as standard with every masonry support system, which must be located between the back of the bracket and the support structure.

Technical Data Sheet

Find out all technical data on IG Masonry Support’s Welded Masonry Support systems in our comprehensive Technical Data Sheet.

Installation of WMS

Correct installation is essential for the success of your project. Therefore, we have made every effort to help you by creating an easy-to-use installation guide for Welded Masonry Support.

Welded Masonry Support Installation Guide (882kb)

Should you have any technical questions prior to or during installation, please call 01283 200157 for friendly straightforward advice.

Specify Welded Masonry Support

Use the National Building Specification’s (NBS) platform to find, select, and incorporate our Welded Masonry Support product information into your next construction project’s specification.

Discuss Your Project

Contact our technical design team to collaborate or enquire about a project.

Contact UsHow to install Welded Masonry Support

Related Products

Projects using these products

Projects using these products

Projects using these products

Projects using these products

Projects using these products

Projects using these products

Projects using these products

Projects using these products

Projects using these products

Projects using these products

Projects using these products

Projects using these products

Projects using these products

Projects using these products

Projects using these products

Projects using these products

Projects using these products

Key Benefits of Welded Masonry Support

Contact Us- Stainless steel - A1 fire-rated material

- Designed for loads up to 50kN/m

- Suitable for larger cavities up to 250mm

- Variety of configurations to suit project requirements

- Onsite adjustability on three planes

- EPD: BRE Global Verified

- Passive House certified component

Request CPD Presentation

Gain your CPD points by requesting a Continuous Professional Development presentation on IG Masonry Support solutions.

Request CPD