- Home

- Masonry Support Systems

- Titan System

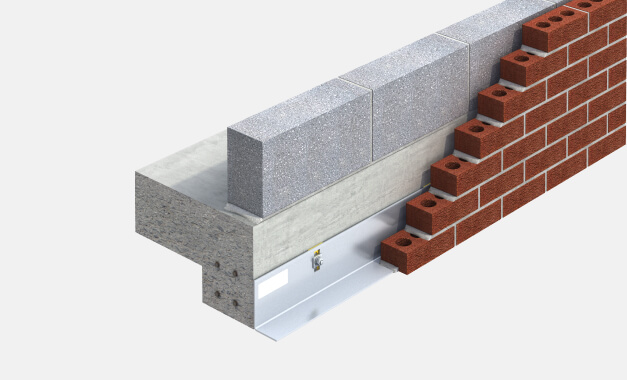

Titan System

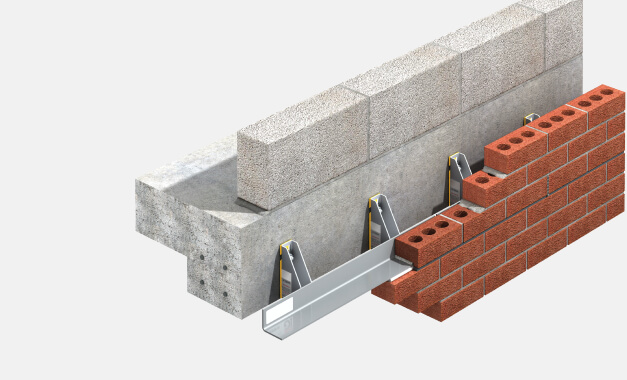

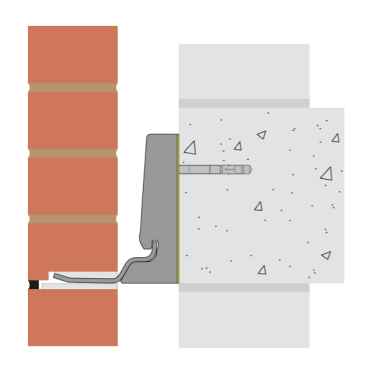

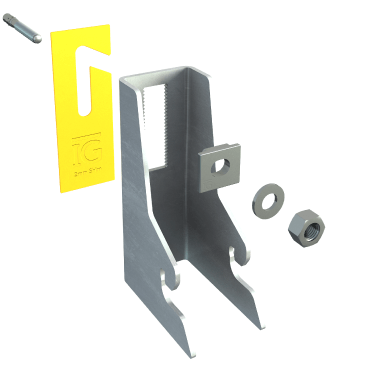

Titan is a standard stocked masonry support solution comprised of a front loaded shelf angle, brackets, lock washers, shims and bolts. This off-the-shelf masonry support solution provides structural engineers with an excellent alternative to Welded Masonry Support.

The front-fit loading of the masonry support shelf facilitates ease of installation, while the bracket system is designed to accommodate typical build tolerance on-site, ensuring accurate installations.

Standard System

There are six IG Titan Systems; Titan 4, Titan 6, Titan 8, Titan 10, Titan 12, and Titan 14. Suitable for concrete and steel framed structures, the design of these systems accommodate masonry loads of up to 4, 6, 8, 10, 12, and 14kN/m, respectively.

Standard brackets are available for cavity widths ranging from 70 to 200mm (stocked in 10mm increments). Brackets are simply changed on-site to allow for cavity variations.

Application

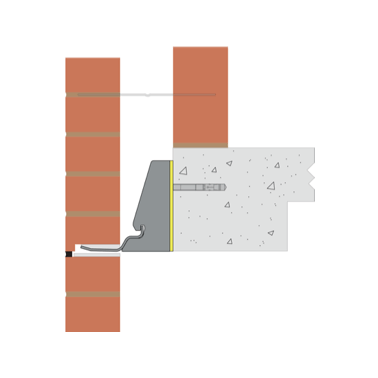

Stainless steel masonry support systems support the outer leaf masonry material on steel or concrete framed structures.

Titan can support any outer leaf masonry material:

- Brickwork

- Fair-face blockwork

- Rendered blockwork

- Reconstituted stone

Standard System

There are six IG Titan Systems; Titan 4, Titan 6, Titan 8, Titan 10, Titan 12, and Titan 14. Suitable for concrete and steel framed structures, the design of these systems accommodate masonry loads of up to 4, 6, 8, 10, 12, and 14kN/m, respectively.

Standard brackets are available for cavity widths ranging up to 200mm (stocked in 10mm increments). Brackets are simply changed on site to allow for cavity variations.

Titan system specification

| System Type | Designed Load (kN/m) | Angle Length (mm)* | Bracket Centres (mm) |

|---|---|---|---|

| Titan 4 | 4 | 1590 | 800 |

| Titan 6 | 6 | 1390 | 700 |

| Titan 8 | 8 | 1190 | 600 |

| Titan 10 | 10 | 990 | 500 |

| Titan 12 | 12 | 990 | 500 |

| Titan 14 | 14 | 790 | 400 |

Bolt specification

| Bolt Type | Fixing to | Drill Hole Diameter (mm) | Torque (Nm) | Supplier Name |

|---|---|---|---|---|

| FAZ II 12/20 A4 | Concrete | 12 | 35 | Fischer |

| RG M 12x120 A4 | Concrete | 14 | 40 | Fischer |

| HD Bolt M12x60 | Steel | 12 | 30 | Blindbolt |

| Set Screw M12x60 | Steel | 14 | 73.5 | Fit-Lock |

| T Head Bolt A2 | Cast-In Channel | 50 |

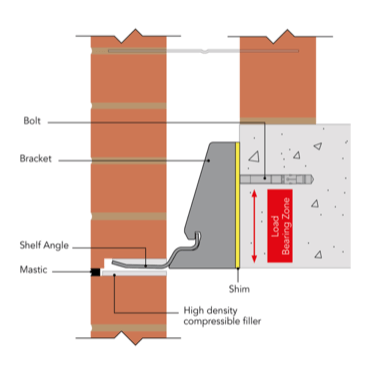

Adjustability of IG Titan System

Our Titan system provides significant adjustability in all three planes to ensure that building tolerances can be accommodated and contact with the reinforcing bar can be avoided.

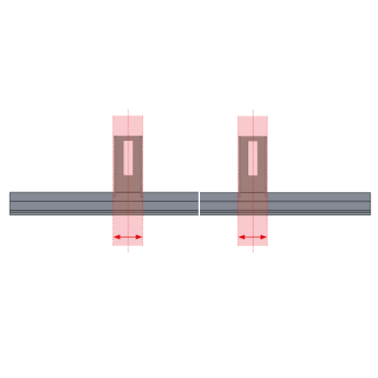

Horizontal Adjustment

IG Titan angles have a 50mm fixing zone which provides +/- 25mm horizontal adjustment from the centre line of the bracket.

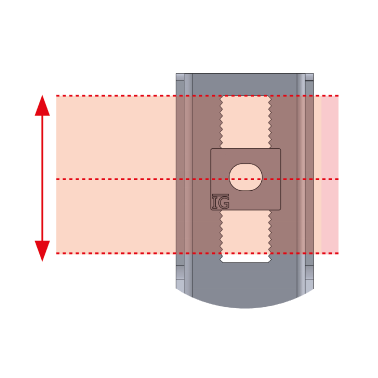

Vertical Adjustment

A toothed Lock Washer enables +/- 15mm of vertical adjustment.

Lateral Adjustment

To accommodate a small increase in cavity width, shims can be inserted between the support structure and the bracket.

Installation of Titan System

Correct installation is essential for the success of your project. Therefore, we have made every effort to help you by creating an easy-to-use installation guide for Titan System.

Titan System Installation Instructions (495kb)

Should you have any technical questions prior to or during installation, please call +44 (0)1283 200157 for friendly straightforward advice.

Discuss Your Project

Contact our technical design team to collaborate or enquire about a project.

Contact UsRelated Products

Projects using these products

Projects using these products

Projects using these products

Key Benefits of Titan System

Contact Us- Quick specification using simple load/cavity charts

- Detailed layout drawings are not required

- Fast installation facilitated by front-loaded shelf angle

- Increased adjustability compared to welded masonry support systems

- Standard stock product

- Unused components can be used on your next project or returned to stock

Request CPD Presentation

Gain your CPD points by requesting a Continuous Professional Development presentation on IG Masonry Support solutions.

Request CPD