Overview

IG Masonry Support has gone above and beyond to provide the highest quality, accredited products in the construction industry. We’ve invested in rigorous manufacturing processes and certifications to ensure our products meet and exceed industry standards.

As a trusted manufacturer, we understand the importance of supporting stakeholders throughout the entire project lifecycle. From design and specification to compliance and safety, we prioritise delivering reliable and sustainable solutions.

Our “Sleep Like a Baby” campaign reflects our dedication to providing architects, engineers, and contractors with peace of mind. When you choose IG Masonry Support, you’re selecting products that are not only safe but also manufactured responsibly to exceed the requirements of the Building Safety Act and other relevant building regulations.

1 .

Third-party tested and certified products

Our masonry support and brick slip products are certified by leading industry bodies, including the BBA, Eurofins, Passive House, and BRE.

We rigorously test products in-house and collaborate with UKAS-accredited labs like Queens University, Belfast, and independent testing facilities such as Lucideon, Warrington Fire, Efectis, and SGS to verify design and performance.

2 .

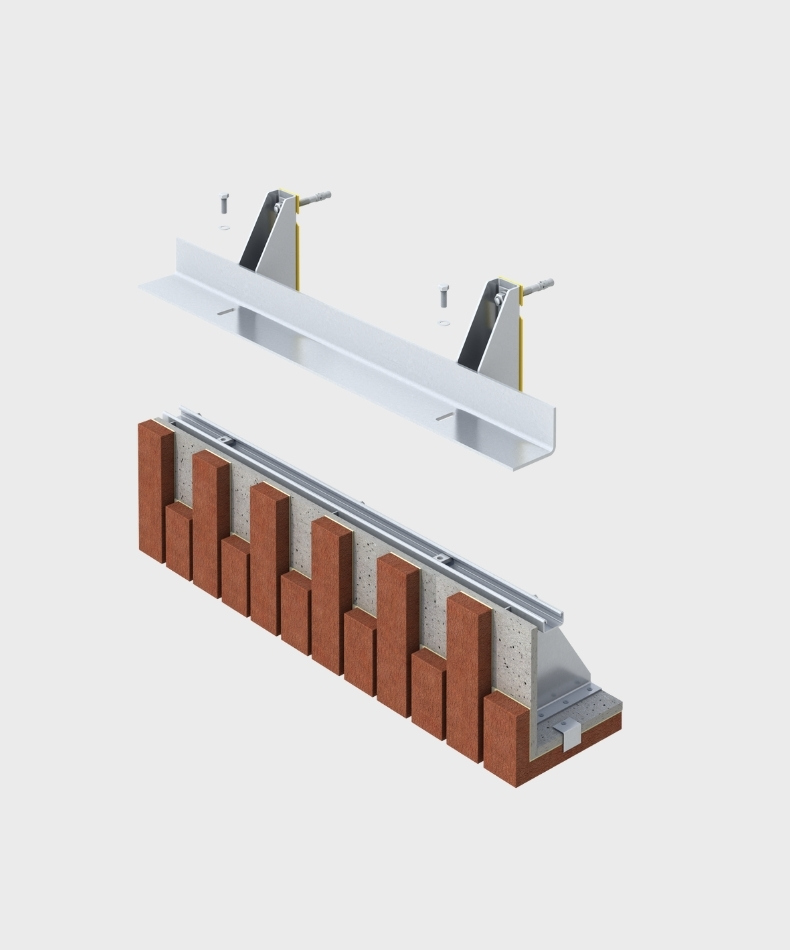

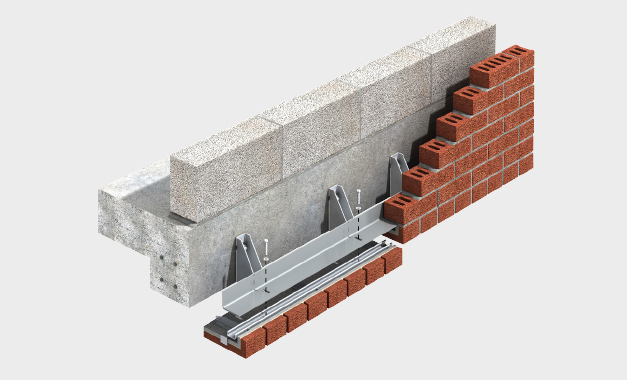

No subcontract manufacturing

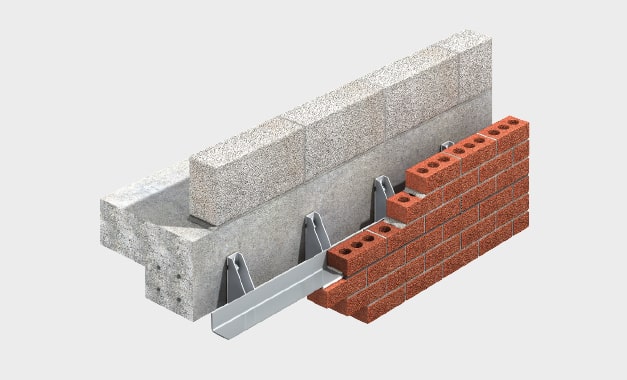

We proudly manufacture all of our masonry support and brick slip systems in-house at our factory in South Derbyshire (UK).

Our facilities are third-party audited to ensure the highest quality of product that meets the required building regulations for each project.

3 .

In-house design and technical support

With an experienced team of over 40 skilled structural and civil engineers, our services extend beyond product supply.

From specification and scheduling, to design, project management and onsite support, our expert team is dedicated to delivering tailored, efficient and compliant masonry support and brick slip solutions for your project.

1 .

Third-party tested and certified products

We have gone above and beyond to ensure our masonry support and brick slip products meet and exceed all requirements in the form of directives, regulations and harmonised standards.

Our range of certifications has been awarded by industry bodies including the British Board of Agrément (BBA), Eurofins, Passive House, and the Building Research Establishment (BRE). We utilise UKAS-accredited equipment at Queens University, Belfast, to verify our masonry support designs and rely on the test facilities of Lucideon, Warrington Fire, Efectis, and SGS for independent tests related to hygrothermal, fire performance, deflection and adhesion. Once we’ve secured certification and launched a new product on to the market, we continue to conduct regular in-house tests to ensure the highest quality standards dictated by our ISO 9001 accreditation.

The level of testing and certification we provide as a responsible supplier makes the specification and acceptance of our products by designers, principal contractors, local authority building control, and the Building Safety Regulator an easy choice.

2 .

No subcontract manufacturing

IG Masonry Support manufacturers all masonry support and brick slip products in-house at our factory in South Derbyshire (UK).

Our manufacturing facilities are third-party audited and certified by the British Board of Agrément (BBA) in accordance to BS EN ISO 9001:2015 and EN 1090-1:2009. As a result, we can ensure the highest quality of product that meets the required regulations for your project.

We were also the first masonry support manufacturer to achieve carbon neutral status and we are on our way to becoming a net zero energy company. This demonstrates our passion and commitment to operating a sustainable business and delivering sustainable solutions to the marketplace.

3 .

In-house design and technical support

IG Masonry Support is proud to employ over 40 skilled structural and civil engineers, dedicated to delivering solutions and services that are world-class and help our customers push the boundaries of their building designs.

By leveraging state-of-the-art design software and industry-leading expertise, we have complete control over the whole design process. We tailor solutions to specific project requirements, ensuring optimal performance, efficiency and regulatory compliance. This streamlined approach fosters seamless communication between design and production teams and allows for greater flexibility and responsiveness to client needs.

Results matter. We’re committed to maximising customer satisfaction, even after delivery our products. Our dedicated Project Engineers will provide ongoing support to ensure your project’s success.

Building Safety Act Compliance

Overview

Our response

The Building Safety Act received Royal Assent in April 2022, updating existing laws like the Building Act 1984, Housing Act 1996, and Fire Safety Act 2021. The Act outlines construction, maintenance, and safety requirements for residential buildings and strengthens rights, powers, and protections for residents and homeowners.

The Health and Safety Executive established the Building Safety Regulator (BSR) under this Act to oversee building work requiring building control approval. The BSR sets standards, enforces building regulations through local authorities, establishes competency requirements, defines statutory roles for designers and contractors, and regulates building control officers.

While the Act applies to all buildings, it introduces a stricter regulatory regime for higher-risk buildings to improve accountability, risk management, and assurance. This new regime includes three “gateways”:

- Gateway 1: Applicants must demonstrate that the proposed design meets safety requirements during the planning stage.

- Gateway 2: The BSR must approve the application before construction begins.

- Gateway 3: The BSR conducts a final inspection and issues a completion certificate before occupancy after construction is complete.

The Golden Thread

Overview

Our response

The Building Safety Act introduces a crucial new compliance element: “the golden thread“. This core record-keeping process tracks a building’s design, construction, and operation. It requires managing, documenting, and making information about the building accessible to ensure understanding and safety. This information management ensures accuracy, currency, security, clarity, and availability to those who need it.

Product manufacturers like IG Masonry Support will face increased scrutiny of their product information. Duty holders, including consultants and contractors, need reliable information about the products they specify and install.

Request an IG Masonry Support CPD

Discover how our products meet Building Safety Act requirements for all building types.

Request CPDAccess our Building Safety Act White Paper

From Legacy to Liability: How the Building Safety Act is Creating a Cultural Shift in Construction

Download a copyDiscuss Your Project

Contact our technical design team to collaborate or enquire about a project.

Contact Us