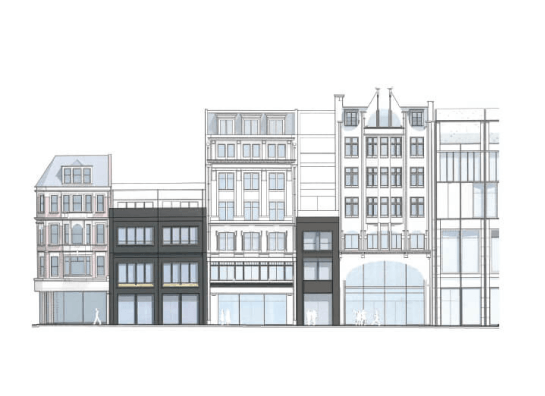

IG Masonry Support developed numerous prefabricated building components for a range of different brick detailing applications, including bespoke glazed brick slip panels as an effective means of creating entire façades of glazed masonry.

The factory produced panels were installed onto Metsec’s steel framing system, providing the contractor with maximum adjustability, ensuring seamless assembly of the elevation onsite. Brick slip columns, varying considerably in height, were a re-occurring architectural feature throughout the residential elements of the scheme.

IG identified a solution capable of achieving columns scaling up to three storeys high. Due to limited storage and handling areas onsite, all prefabricated components were designed in manageable sizes and delivered in accordance with the just-in-time inventory strategy employed onsite. IG produced prefabricated glazed brick slip panels for the front retail façades at Schuh Kids and Sketchers, utilising grey and gold Pyrolave glazed brick types. IG liaised with Metsec to ensure the steel framing system and glazed panels worked together to facilitate this safe onsite installation.

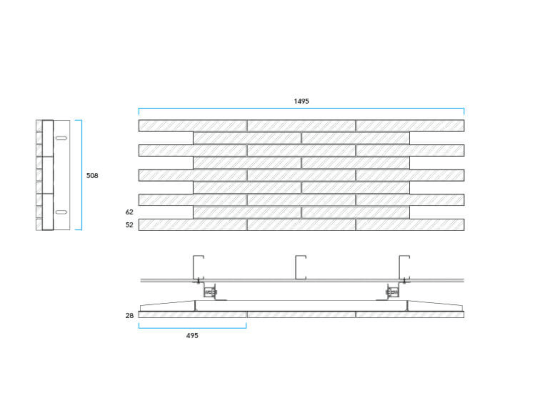

Panels were designed in manageable components that could be lifted by hand. The interlocking units slotted together to achieve the bond pattern throughout each elevation, accommodating the two different brick types. The brick slip columns were produced in various sizes from 2m to 3.4m in height and accommodated two different brick types, Charnwood Coral red and Stamford Buff. The base and top plate of the columns bolted together allowing the contractor to connect units as they advanced up each storey. The highest column assembly was 9950mm consisting of three columns, restrained to the building’s steel frame at each level.