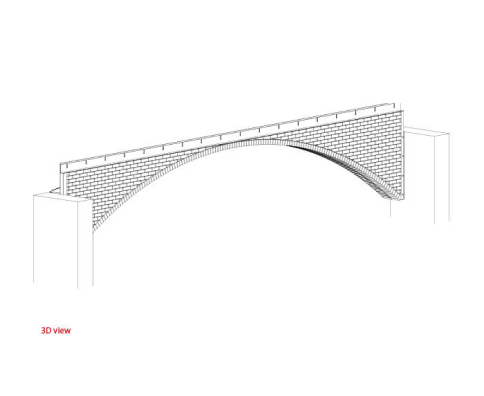

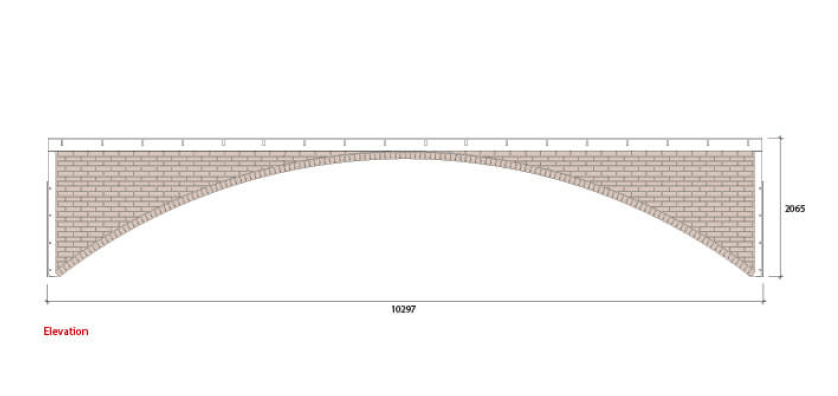

Due to the sheer size of the installation, the brick slip bridge panels were produced and delivered to site in two separate components and fixed together onsite through bolt connections.

Situated within the heart of London, delivering components in two parts also made logistical sense. The panels were delivered and installed on the same day, lifted in by crane and bolted into place. Matching the brick requirements on site ensured that the bridge blended seamlessly with already constructed brickwork.

IG’s prefabricated panels ensured no formwork was required to create a deep brick soffit on the underside of the bridge, streamlining the process and saving considerable time on-site. The bridge at Chelsea Creek demonstrates IG Masonry Support’s design creativity when it comes to bespoke brick slip components, helping to achieve even the most complex architectural designs with modern off-site building practices.