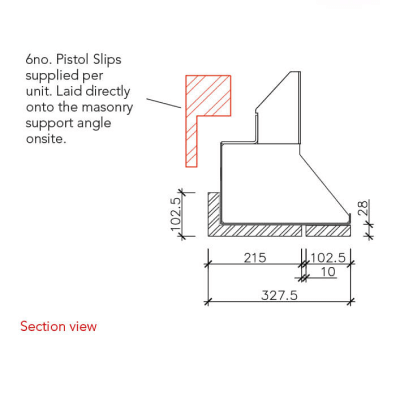

IG’s technical team needed to develop a system to accommodate a range of different cavity widths including some over 300mm wide.

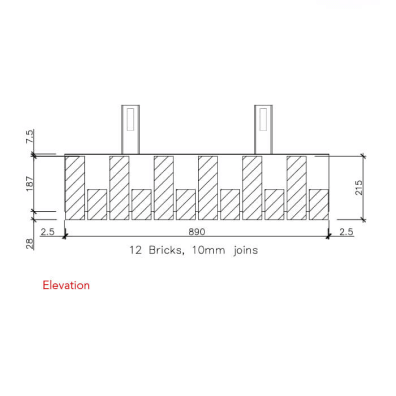

Each residential block would be distinguished by numerous brick types and bond patterns. The diverse range of brick slip components required needed to accommodate a combination of industrial engineering bricks and various glazed brick types.

The challenge on this project was to develop a system that could allow for stretcher on end bond pattern and also develop DPC detail to accommodate the staggered bricks.

IG’s brick slip systems offer fast, lightweight solutions capable of accommodating any bond pattern.

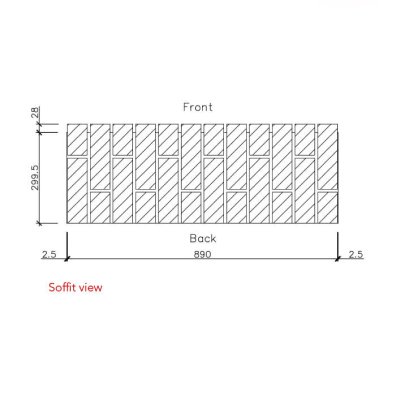

The development required a combination of brick slip lintels and brick slip masonry support. Utilising prefabricated components would help speed up the pace of construction, helping to reduce labour costs.

Produced offsite, IG Masonry Support’s brick slip components are manufactured within a strict quality controlled environment. Factory conditions mean that work is not delayed by factors such as weather other trades. Components are delivered to site as required ready for installation and final pointing.

IG Masonry Support developed a unique DPC detail, accepted by both Architect and NHBC, allowing the stretch on end bond pattern to proceed.

Main Contractor

SISK

Brickwork Contractor

Lee Marley Brickwork

Architect

Hawkins Brown

Location

Clapham Junction, South West London

Products Used

Brick Slip Lintels

B.O.S.S.

Welded Masonry Support

Contact our technical design team to collaborate or enquire about a project.

Contact Us

Gain your CPD points by requesting a Continuous Professional Development presentation on IG Masonry Support solutions.

Request CPD

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |